Choosing the right food processing equipment is crucial for any business in the food industry. Experts like John Smith, a renowned consultant in food technology, emphasize, “The right equipment can significantly improve efficiency and product quality.” However, the selection process is often complex.

When considering food processing equipment, factors such as capacity, scalability, and maintenance must be evaluated. Your needs may change over time. Equipment that works well today might not suit future demands. This reality can lead businesses to overspend on equipment that becomes obsolete.

Thoughtful consideration is essential. You want equipment that meets current and future needs while maximizing productivity. Many companies have made costly mistakes by overlooking important details. Investing time in understanding your specific requirements is vital. Remember, the right choice in food processing equipment can be a game changer.

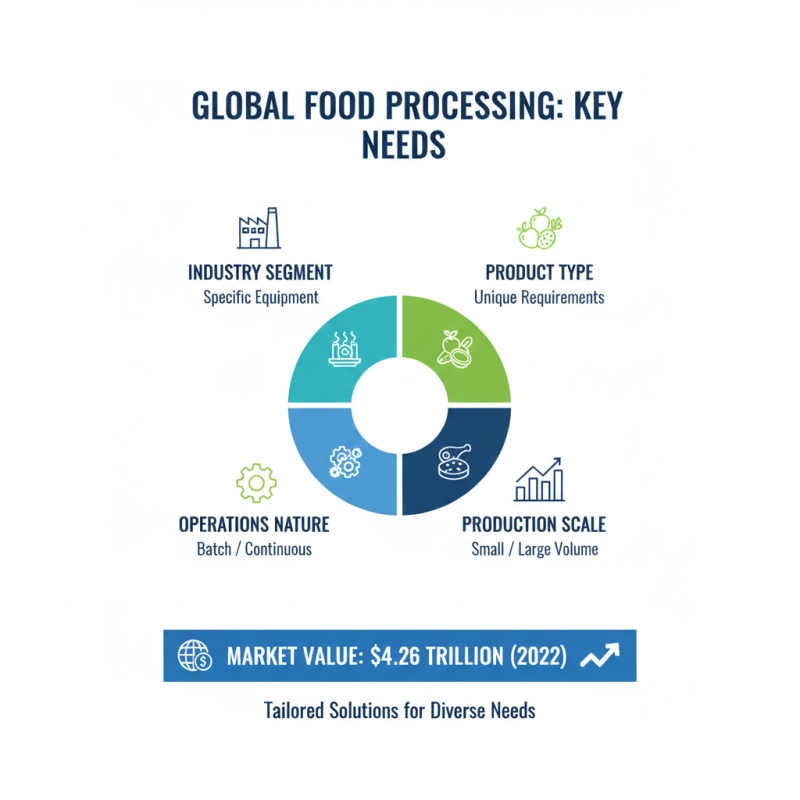

Understanding your food processing needs is crucial. Every segment of the industry requires specific equipment. The global food processing market was valued at approximately $4.26 trillion in 2022, reflecting its vast scope. Different products have unique requirements. Manufacturers must consider the nature of their operations and the scale of production.

Assessing the type of food processed is essential. For instance, wet processing requires different machines compared to dry processing. If you handle perishable goods, equipment with efficient preservation features is vital. In a recent survey, 70% of food processors indicated that choosing the right equipment directly impacts product quality. However, many still struggle with aligning their machinery with processing needs.

Budget constraints can lead to hasty purchases that don't match operational demands. A recent report revealed that 65% of food manufacturers regretted their equipment investments within the first year. Sometimes, equipment doesn't meet production rates, or maintenance becomes cumbersome. Continuous reflection on equipment performance is key. Adapting to evolving requirements can prevent costly mistakes and ensure efficiency in food processing.

When evaluating types of food processing equipment, it’s crucial to understand the market's diversity. Data shows that the global food processing machinery market is projected to grow significantly, reaching over $70 billion by 2025. This growth implies an extensive range of options, from mixers and blenders to more complex machinery like processing lines and packaging systems. Each type serves unique needs in food production, which makes selection critical.

Consider the specific requirements of your operation. If you handle high volumes, automated equipment may be necessary. Expert reports suggest that automation can enhance efficiency by up to 30%. However, investing in advanced machinery can be a gamble if not properly assessed. Maintenance is another concern; neglected equipment can lead to costly downtimes. The type of materials used in machinery also matters significantly. Food-grade stainless steel is often recommended for hygiene, but it can be expensive.

The learning curve for new equipment can be steep. Training staff efficiently is essential to maximize equipment capabilities. Some producers find themselves grappling with equipment that is not user-friendly. This can lead to poor performance and increased operational costs. Industry stats indicate that over 20% of equipment purchases may not meet the intended operational needs, highlighting the importance of comprehensive evaluations before investing.

When selecting food processing equipment, quality and durability are key. The right machines will withstand repeated use and rigorous conditions. Look for materials that resist corrosion and damage. Stainless steel or food-grade plastics are often preferred. Additionally, equipment should have a solid build to prevent issues during operation.

Tip: Always check the warranty. A longer warranty often indicates confidence in the product’s durability. It can save costs and frustration in the long run.

Inspect the equipment's maintenance requirements. Some machines may need frequent upkeep, while others are more low-maintenance. Ease of cleaning is also important. Complex designs can trap food particles, leading to contamination risks.

Tip: Read user reviews to gauge real-life performance. Sometimes, specifications seem perfect, but actual experiences reveal flaws. Take note of any common complaints regarding durability. Be wary of overly positive reviews, as they may not always reflect the truth.

| Tip No. | Criteria | Description |

|---|---|---|

| 1 | Material Quality | Ensure equipment is made from food-grade, durable materials resistant to wear and tear. |

| 2 | Energy Efficiency | Choose machines with lower energy consumption to reduce costs and environmental impact. |

| 3 | Ease of Cleaning | Select equipment that is easy to disassemble and clean to maintain hygiene standards. |

| 4 | Operational Capacity | Evaluate if the equipment can handle the volume of production you require. |

| 5 | Safety Features | Consider machines with built-in safety mechanisms to protect operators. |

| 6 | Warranty and Support | Look for equipment that comes with a solid warranty and reliable customer support. |

| 7 | Scalability | Assess whether the equipment can be scaled up or adapted as your production needs evolve. |

| 8 | User-Friendliness | Ensure the controls and interface are intuitive for operators to minimize training time. |

| 9 | Performance Track Record | Research past performance and reliability through reviews or case studies. |

| 10 | Regulatory Compliance | Verify that the equipment meets local and international food safety regulations. |

When choosing food processing equipment, budget constraints are a critical factor. According to a report by IBISWorld, the food processing industry in the U.S. is expected to reach $800 billion by 2024. Investing in high-quality equipment can have long-term benefits. However, upfront costs may limit options for some businesses. It is essential to balance initial expenditure with expected longevity and efficiency.

Consider the life cycle of the equipment. Cheaper machines may save money initially but often require more frequent repairs. A report from Technavio highlights that investing in durable equipment can reduce maintenance costs by 30% over five years. A penny saved today can lead to more costs later. Think about energy efficiency, too. Energy Star-rated equipment can significantly lower energy bills, providing savings that can offset the initial investment.

Also, consider financing options. Many suppliers offer leasing or financing plans, making it easier to acquire quality equipment. A study from the National Restaurant Association notes that 65% of businesses use financing for major purchases. While it can be tempting to choose the cheapest option, reflect on the potential impact on productivity and food quality. Long-term investments often yield greater returns.

When selecting food processing equipment, considering the manufacturer's reputation is vital. A company's credibility often reflects the quality of their products. Look for reviews from previous customers. User experiences can reveal a lot about reliability and performance. However, be cautious of overly positive reviews. They might not represent the whole picture.

Customer support options are equally important. A responsive support team can significantly ease troubleshooting issues. Check if they offer installation assistance or training sessions. These services can save time and reduce operational hiccups. Sometimes, support is lacking even from well-rated companies. This gap can lead to frustration when problems arise.

Evaluate the manufacturer's response time. Quick replies indicate good customer care. Also, investigate their warranty policies. A strong warranty can signal confidence in their equipment. However, not all warranties cover every scenario. You might find unexpected exclusions. Researching these details can lead to a more informed decision.

This bar chart showcases the importance of various factors when choosing food processing equipment. The ratings reflect how crucial each aspect is based on industry standards and feedback. Manufacturer reputation and equipment quality scored the highest, indicating they are critical in the decision-making process.

JK Machinery a.s.

Psohlavců 322/4, Praha 4,

Czechia

T: +420 777 610 380

E: sale@roll-formingmachinery.com