Choosing the right machinery equipment for your business is crucial. It directly affects productivity, efficiency, and cost. Many businesses overlook this important decision. They often rush into purchasing equipment without thorough research. This can lead to substantial losses and operational challenges.

Understanding your specific needs is essential. Consider the nature of your work, and the types of projects you handle. Each piece of machinery equipment must align with your goals. Evaluate the long-term benefits of each option. Sometimes, the cheapest option may not be the best choice. Quality and reliability often matter more.

Don’t forget to involve your team in these discussions. Their insights can highlight equipment needs you might miss. Machinery equipment can also impact workplace safety. Neglecting this aspect could result in risk and injury. Reflect on past experiences with equipment choices. Learning from mistakes can guide better decisions in the future.

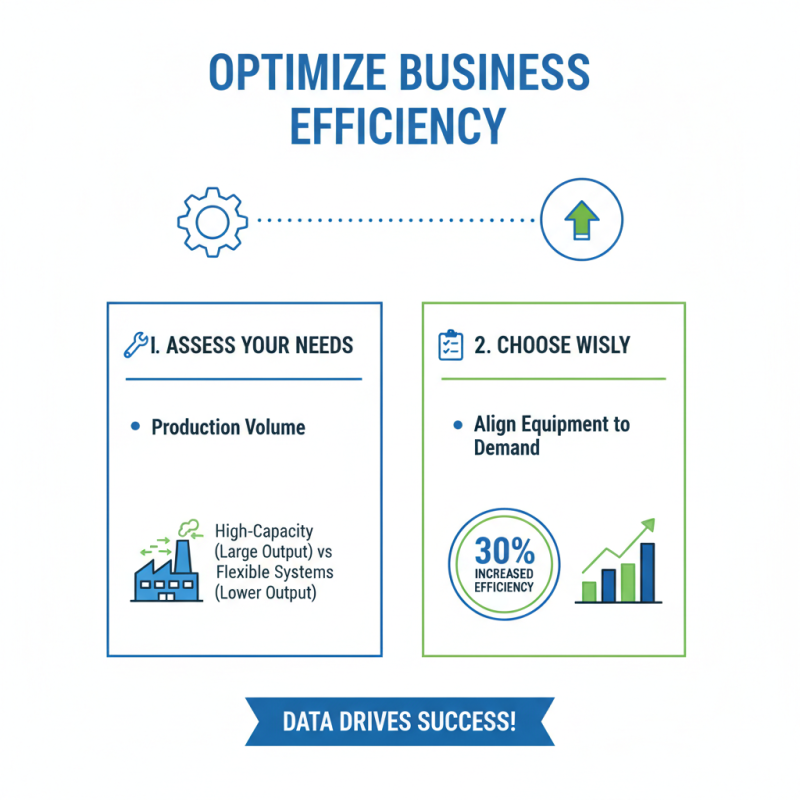

Choosing the right machinery for your business starts with a clear understanding of your unique needs. Assess your production volume. Data shows that companies that align their equipment choices with operational demand can boost efficiency by up to 30%. Knowing if you need high-capacity machinery or flexible systems for lower outputs is critical to your success.

Consider your long-term objectives. Industry reports indicate that firms that invest in technology with growth in mind see an average increase in ROI of about 20%. If your goals include expansion or diversification, machinery that adapts to various products is essential. However, don't overlook maintenance needs. Equipment can require constant attention, leading to unforeseen downtime which affects productivity.

Evaluate your budget carefully. While investing in high-end machinery may seem tempting, it often leads to financial strain without guaranteed returns. It’s essential to remember that the cheapest option can lead to higher operational costs in the long run. Every choice should reflect a balance between cost and operational efficiency.

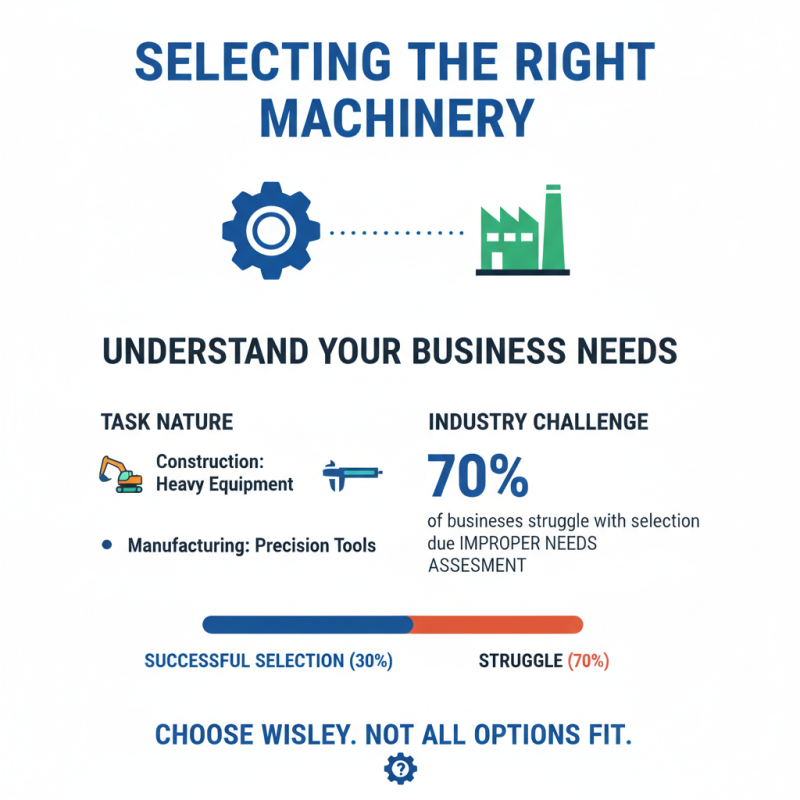

When evaluating different types of machinery equipment, understanding the specific needs of your business is crucial. For instance, consider the nature of the tasks at hand. Heavy equipment may be necessary for construction, while precision tools are vital in manufacturing. A recent industry report indicates that 70% of businesses struggle with selecting the right machinery due to improper assessment of their requirements. Many equipment options exist, and not all will fit your business model.

Cost is another significant factor. The initial investment is just part of the equation. Maintenance costs, energy consumption, and labor expenses matter too. The machinery should enhance productivity but not drain your budget. Research reveals that companies that prioritize cost-benefit analysis see a 25% improvement in operational efficiency. However, many overlook this, leading to long-term financial strain.

Lastly, think about future needs and scalability. Equipment that meets current demands might not suffice as your business grows. Flexibility in machinery selection can prevent costly replacements later. A study found that 60% of businesses failed to future-proof their equipment choices. Reflecting on this may achieve sustainable growth, saving time and resources in the long run.

Choosing the right machinery equipment is crucial for any business. Several factors influence this decision. First, consider the specific needs of your operations. What tasks require equipment? Identify your priorities. For instance, if efficiency is vital, look for advanced machinery that enhances productivity.

Budgeting is another key factor. What can you afford? It’s easy to overspend on shiny new tools. Determine the long-term costs too. Maintenance, repairs, and energy consumption add to overall expenditure. Sometimes, second-hand equipment can be a wise investment. Reflect on the trade-offs between cost savings and potential inefficiencies.

Evaluate the machinery's scalability. Will it grow with your business? Sometimes, a piece of equipment seems ideal now but may quickly become obsolete. Balance current needs with future demands. Finally, consider support and training. Equipment is not just hardware; it comes with a steep learning curve. Having the right training is essential for proper utilization.

| Factor | Description | Importance Rating (1-5) | Estimated Cost |

|---|---|---|---|

| Capacity | The amount of work the machinery can handle within a given time. | 5 | $20,000 - $100,000 |

| Durability | The expected lifespan and robustness of the equipment. | 4 | $15,000 - $80,000 |

| Maintenance | The ease and cost of maintaining the equipment. | 3 | $2,000 - $10,000 per year |

| Energy Efficiency | The amount of energy consumed in relation to output. | 5 | $500 - $5,000 more upfront |

| Scalability | The ability to increase capacity or adaptability to changing needs. | 4 | $10,000 - $50,000 |

| Compliance | Meeting regulatory standards or safety requirements. | 4 | Varies widely |

When considering machinery for your business, budgeting is crucial. Start by assessing your financial situation. Determine how much capital you can allocate. For many, priorities get blurred, especially with tempting high-tech options. It's easy to overspend when you're excited. Keep your needs realistic.

Create a clear budget breakdown. Include costs like purchase price, maintenance, and operational expenses. Don't forget about financing options. Lease agreements can be appealing. Yet, they may lead to long-term costs. Calculate what works best for your financial health.

Next, consider potential returns. Will the new equipment enhance productivity? Or will it add unnecessary costs? Make a list of your business goals. Reflect on how machinery might fit these objectives. This reflection can clarify whether you truly need that high-end model or a simpler version suffices.

When choosing the right machinery for your business, vendor research is crucial. Start by identifying local suppliers who specialize in your required equipment. Get recommendations from peers. Check online forums, and consider trade shows to find reliable vendors.

Quality equipment impacts productivity. Look for manufacturers with a solid reputation. Reviews can reveal strengths and weaknesses. A vendor may have great reviews, but their customer service might fall short. Pay attention to details like warranties and service agreements. Sometimes, seemingly small issues can lead to significant problems.

Visiting vendor facilities offers insights into operations. Observe their workspace and staff professionalism. This can help gauge their reliability. Also, don’t hesitate to ask questions about sourcing materials and production processes—transparency is key. Factors like price should not overshadow quality and support. Balancing these elements is essential, as cutting corners can jeopardize your business's success.

JK Machinery a.s.

Psohlavců 322/4, Praha 4,

Czechia

T: +420 777 610 380

E: sale@roll-formingmachinery.com