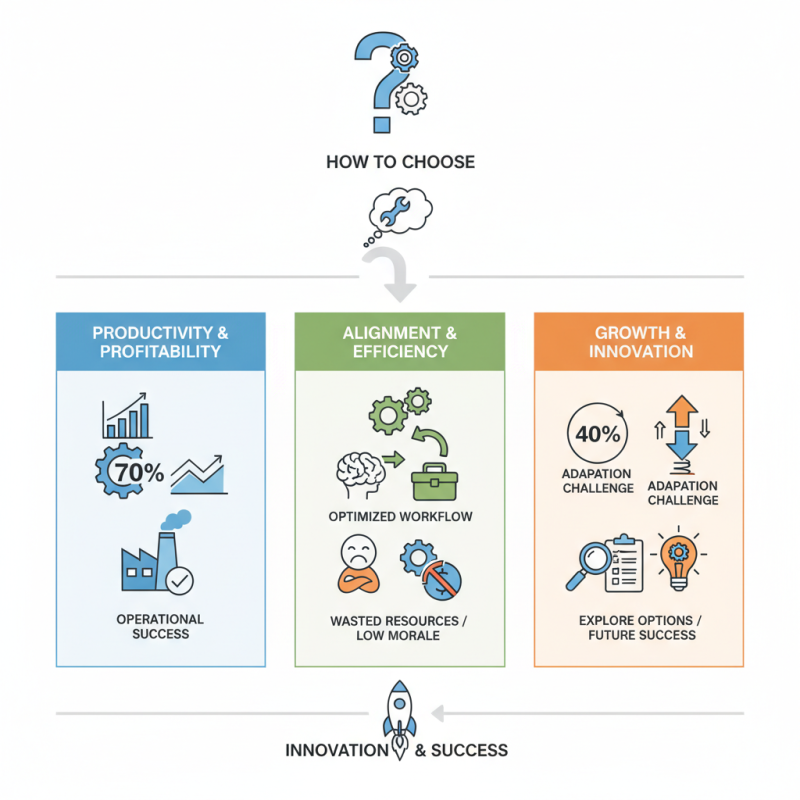

Choosing the right industry equipment is a pivotal decision for any business. In today's competitive landscape, selection can influence productivity and profitability significantly. According to a recent report by the National Association of Manufacturers, about 70% of companies cite machine performance as critical to operational success. Ensuring your equipment aligns with your business goals is essential.

Industry expert Mark Johnson emphasizes, "The right tools can transform an ordinary workflow into a highly efficient process." His insights reflect a common challenge: many businesses invest in equipment that does not meet their specific needs. This mismatch can lead to wasted resources and lower employee morale.

The choice of industry equipment should not be taken lightly. Industrial growth reports suggest that 40% of firms that fail to adapt their equipment often struggle to keep pace with competitors. Understanding your requirements and exploring options is key to avoiding pitfalls. Reflecting on equipment decisions can pave the way for future innovation and success.

Understanding your business needs and objectives is crucial when selecting industry equipment. Identifying specific requirements helps streamline your operations. A recent report from the International Equipment Association indicated that companies tailoring their equipment choices to their operational needs saw a 25% boost in efficiency. Not every piece of equipment is suitable for all businesses. Customization may lead to higher initial costs but can result in long-term savings.

Consider the scale of your operations. Investing in oversized machinery can strain your budget. Conversely, under-equipped setups may limit growth potential. A study by the National Manufacturing Association found that 40% of small businesses faced setbacks due to inadequate equipment. Therefore, knowing your production goals is essential. Define your target output levels clearly, aligning equipment choices with these objectives.

It's also important to evaluate the adaptability of the equipment to future changes. Industry dynamics shift, and your needs may evolve. Flexibility in equipment can be a double-edged sword; it offers potential but can also complicate maintenance. Balancing these factors is key. Aim to choose equipment that meets current demands while allowing room for expansion.

Choosing the right industry equipment is vital. Understand the types available in your sector. For instance, in manufacturing, equipment varies widely. Machinery like CNC machines and robotic arms can enhance productivity. According to recent reports, 70% of manufacturers see a return on investment in such technology within two years.

In the construction industry, equipment such as excavators and bulldozers is crucial. However, many businesses overlook maintenance. A study highlighted that 30% of contractors report delayed projects due to equipment failure. This statistic underscores the importance of considering reliability alongside capability.

In the food and beverage sector, processing equipment quality can influence product safety. Compliance with regulations is non-negotiable. A report from industry analysts showed that 45% of food recalls were linked to equipment issues. Companies must balance initial costs with long-term safety and efficiency. Choosing wisely can impact not only productivity but also brand reputation.

When evaluating equipment quality, several key factors come into play. First, durability is essential. A 2022 report from the Industrial Equipment Research Council indicated that equipment lasting over ten years can reduce total costs by nearly 30%. This longevity means fewer replacements, which is crucial for budget-conscious businesses. Moreover, maintenance frequency plays a significant role. Equipment that requires frequent repairs can quickly erode profits and disrupt operations.

Reliability should not be overlooked. Studies show that inconsistent equipment performance can lead to operational delays. In fact, around 25% of businesses reported downtime due to equipment failures in a recent survey. It's vital to consider the equipment's track record and user reviews. Investing time in assessing equipment through hands-on trials can provide insight into its functionality. Remember, not all high-priced items guarantee superior quality. Evaluate the specifications and seek user feedback to make informed decisions.

In the end, the right equipment must align with your specific needs. Some businesses rush into purchasing decisions, only to realize the choice was not ideal. Reflect on your unique operational requirements and budget constraints. Quality equipment should not be a source of stress but an asset to enhance productivity.

When investing in industry equipment, budgeting is crucial.

A recent report from the National Association of Manufacturers indicated that nearly 56% of small businesses face financial constraints when upgrading equipment. This makes it essential to evaluate costs carefully. Consider not just the purchase price.

Maintenance, training, and operational costs can add up.

Many businesses overlook the total cost of ownership. Equipment might seem affordable upfront but can lead to high long-term expenses. For instance, a study found that companies that plan a budget often save up to 30% on equipment-related costs.

It's important to set a realistic budget, one that allows for contingencies.

Also, consider financing options. Some businesses may find leasing more beneficial than purchasing. Leasing can provide flexibility, but be cautious. A poorly structured leasing agreement can lead to unexpected costs. Beyond that, reflect on how equipment affects the overall budget.

It’s easy to focus only on the price tag, missing hidden financial implications.

Understanding these aspects can lead to better equipment choices and ultimately, business success.

Choosing the right industry equipment goes beyond just specifications and pricing. Vendor reputation plays a critical role. A strong vendor can enhance your operations significantly. They should have a proven history in reliability and service. According to a recent industry report, 70% of businesses see improved output when partnering with reputable vendors. Research potential vendors carefully. Look for customer testimonials and case studies. These insights can reveal much about their reliability.

**Tip:** Ask for references from similar businesses. You’ll get firsthand insights into their support services.

In addition to reputation, vendor support services are vital. Equipment can fail, and quick responses are crucial. A 2022 study found that downtime can cost businesses an average of $250,000 per hour. This means delays can affect your bottom line. Make sure the vendor has a strong support system in place. Check their response times and service options. Companies often overlook this, leading to significant operational disruptions.

**Tip:** Evaluate support offerings during the decision-making process. Understanding post-sale services is equally important as product features.

JK Machinery a.s.

Psohlavců 322/4, Praha 4,

Czechia

T: +420 777 610 380

E: sale@roll-formingmachinery.com