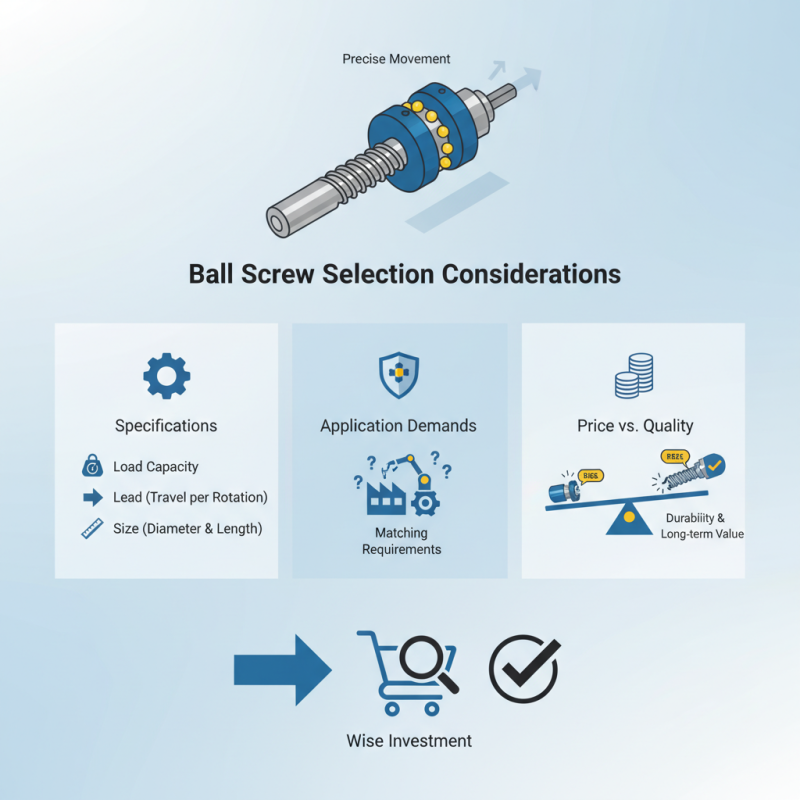

When looking for a ball screw for sale, it's vital to understand what you need. A ball screw plays a crucial role in machinery, ensuring precise movement. The right choice can impact performance and efficiency.

Consider the specifications of the ball screw. Factors like load capacity, lead, and size are essential. Not every option will fit your requirements. Think about your application and what demands you may have.

Price is another factor to weigh. A lower price may seem attractive, but quality matters. Sometimes, cheap ball screws lack durability. Investing in a reliable product can save you money in the long run. Assess the balance between cost and quality carefully.

When selecting the best ball screw for your needs, several factors come into play. The load capacity is crucial. It determines how much weight the screw can handle. Calculate the maximum load before purchasing.

Another important aspect is the lead. This is the distance the nut moves with one complete screw rotation. For faster movements, choose a larger lead. Pay attention to the diameter of the screw as well. A wider diameter often means greater strength, but it also takes up more space.

**Tip:** Always evaluate the environment where the screw will operate. If it's dusty or wet, consider the material and protective coatings.

Precision is also essential. Gaps in tolerances can lead to performance issues. Ensure the ball screw meets your accuracy requirements. Examine the expected wear and tear over time. Have a plan for maintenance or replacements if necessary.

**Tip:** Drawing a diagram of the assembly can help visualize how the ball screw fits into the overall design. This clarity can prevent costly mistakes.

Don’t forget to research available options and their specifications. Analyze reviews, but remember, every application is unique. Reflect on your specific requirements to make the best choice.

When considering a ball screw for your mechanical projects, material composition is crucial. The choice of material directly influences performance and durability. Steel is a prominent option due to its strength and resistance to wear. Aluminum, while lighter, may not offer the same longevity. Industry reports indicate that ball screws made from high-grade steel exhibit a lifespan of up to 25,000 hours under optimal conditions.

Corrosion resistance is another key factor. Stainless steel can resist rust but is often heavier than regular steel. This weight difference can affect machine handling. Moreover, composite materials are emerging in the industry. These materials provide a balance between weight and strength. However, they may lack the durability needed for heavy-duty applications. Inconsistent manufacturing processes can also lead to variances in performance.

Testing the chosen materials in real-world applications can be revealing. Some users report that even minor flaws in materials can lead to significant performance degradation. Adjusting for these issues can be challenging. Overall, selecting the right material is not a straightforward task and requires careful analysis of needs versus available options.

When choosing a ball screw, understanding load capacity is crucial. Load capacity is measured as static or dynamic loads. Static load refers to the maximum load a screw can handle when stationary. This is important for applications where the screw will bear weight without movement. Dynamic load, on the other hand, measures the maximum load when the screw is in motion.

The difference between these ratings impacts your selection. A screw may have a high dynamic load rating but a lower static load capacity. This discrepancy can lead to potential failure in certain circumstances. Imagine using a screw designed for high-speed applications in a static setup. It may not support the weight properly, causing operational issues.

Consider your specific application needs. In some cases, you might be tempted by lower-priced options. However, this decision can seem wise until performance falls short. Look for a balance between cost and quality. Weight tolerances should also align with your project demands. Prioritize understanding these load ratings to avoid expensive mistakes.

When considering a ball screw for your project, accuracy is key. The precision standards you choose will directly affect performance. Often, people overlook the importance of measurement techniques used during production. These techniques determine how well a ball screw can perform under various conditions.

Different applications demand different levels of accuracy. For instance, a CNC machine requires higher precision than a simple conveyor system. Misunderstandings about what constitutes “precision” can lead to costly mistakes. A measurement that seems adequate in theory might fall short in practice. This highlights the need for rigorous testing and validation.

Additionally, look into how the manufacturer measures their ball screws. Do they use advanced tools? Are the tolerances adequately reported? Even small deviations can cause significant issues in high-precision environments. Always ask for accuracy specifications. Sometimes, the finer details can be a game-changer in ensuring reliability and performance. Don’t rush the decision—take your time to understand what truly matters.

When considering a ball screw purchase, cost-effectiveness plays a vital role. Buyers often struggle to balance quality with budget. Quality ball screws can enhance performance but may come at a higher price. It's essential to evaluate your specific application needs and production environment.

One common mistake is solely focusing on upfront costs. While cheaper options may seem appealing, they can lead to higher maintenance costs. A low-quality ball screw might fail sooner, leading to downtime and additional expenses. Investing in a durable product often pays off in the long run.

Tips: Always check the specifications that matter for your application. Understanding load requirements is key. Don't hesitate to ask for technical support if needed. It's worth taking the time to assess both short-term and long-term costs. Quality should not be sacrificed for a lower initial price. A well-made ball screw can truly save you money over time, despite the initial investment.

JK Machinery a.s.

Psohlavců 322/4, Praha 4,

Czechia

T: +420 777 610 380

E: sale@roll-formingmachinery.com