In the food processing industry, maintaining cleanliness is crucial. Effective cleaning ensures food safety and compliance with health regulations. When selecting food processing cleaning equipment, several factors come into play. Many options exist, each serving unique purposes.

Choosing the right tools is often overwhelming. Some may overlook the importance of equipment design or ease of use. Others might prioritize cost over efficiency. Details matter; a small oversight can lead to bigger problems. Proper cleaning processes protect not only the product but also the workers involved.

Investing in high-quality food processing cleaning equipment is wise. Yet, one should consider compatibility with existing systems. Evaluating the durability and maintenance needs is equally important. Many businesses may neglect regular upkeep, leading to inefficiencies. Reflecting on these aspects promotes a more hygienic work environment, essential for any food processing operation.

When selecting food processing cleaning equipment, several factors come into play. The specific requirements of your operation are paramount. Identify the types of food products you handle. Equipment should align with your production standards. Consider the level of contamination. Different equipment offers varying capabilities for cleaning grease, organic matter, and allergens.

Another critical aspect is the ease of use. Complicated machinery can lead to errors. Training staff takes time and effort. Keep maintenance in mind. Equipment that breaks down frequently can hinder production. It’s essential to prioritize durable options that minimize downtime.

Evaluate the size and layout of your facility. Equipment must fit within your existing workspace. Overly large machines can create congestion. Ask yourself about the cleaning frequency required. Not all machinery needs cleaning after each use. Choosing the right schedule is vital. It can affect equipment longevity and food safety. Inadequate cleaning might lead to health risks. Thus, reflection on your current processes is necessary.

When selecting food processing cleaning equipment, understanding the types available is crucial. Different equipment serves specific cleaning needs. High-pressure washers are ideal for heavy-duty tasks. They remove tough grime on surfaces.

Automated scrubbers are efficient for large floor areas. They can reduce labor time significantly.

Conveyor belt cleaners are necessary in food processing. They prevent contamination and ensure hygiene. Steam cleaners are also versatile. They provide chemical-free cleaning, which is essential in food environments. Additionally, portable cleaning systems offer convenience for smaller areas.

Not all equipment suits every situation. Some may not reach tight spaces effectively. Others might require extensive training for operators. Regular maintenance is key to prolonging the life of any machine. Users need to stay vigilant about equipment cleaning effectiveness. It’s a cycle of improvement and adaptation.

When choosing food processing cleaning equipment, efficiency and effectiveness are key. Efficiency means how quickly the equipment can clean. Effectiveness refers to how well it eliminates contaminants. Both factors ensure food safety and quality.

One way to evaluate equipment is to look at its cleaning speed. Faster equipment helps keep production flowing. However, if it doesn't clean thoroughly, it defeats the purpose. Reviewing cleaning cycles is essential. Some machines might seem efficient, but they require extra time for manual cleaning.

Tips: Consider equipment that offers adjustable cleaning settings. This way, you can tailor the process based on the stains or residues. Also, check user feedback for real-world performance. Some machinery might appear well-designed but may struggle in actual use. Always analyze what works for your specific needs, not just general claims.

When selecting food processing cleaning equipment, understanding compliance standards is vital. Regulations are often stringent. Equipment used must prevent cross-contamination. Different regions have varying safety requirements that affect cleanliness and sanitation practices.

Take note of materials used in cleaning equipment. They should be durable and non-porous. Stainless steel or food-grade plastics are common choices. However, maintenance of these materials is often overlooked. Small scratches may harbor bacteria, leading to potential violations of compliance standards. Regular inspections are essential to ensure continued compliance.

Training staff on compliance is crucial. Employees must understand safety protocols and best practices. Regular training sessions can help minimize risks. Yet, many organizations underestimate the need for continuous education. Safety is an ongoing commitment, not a one-time task. Encourage a culture of accountability throughout the facility.

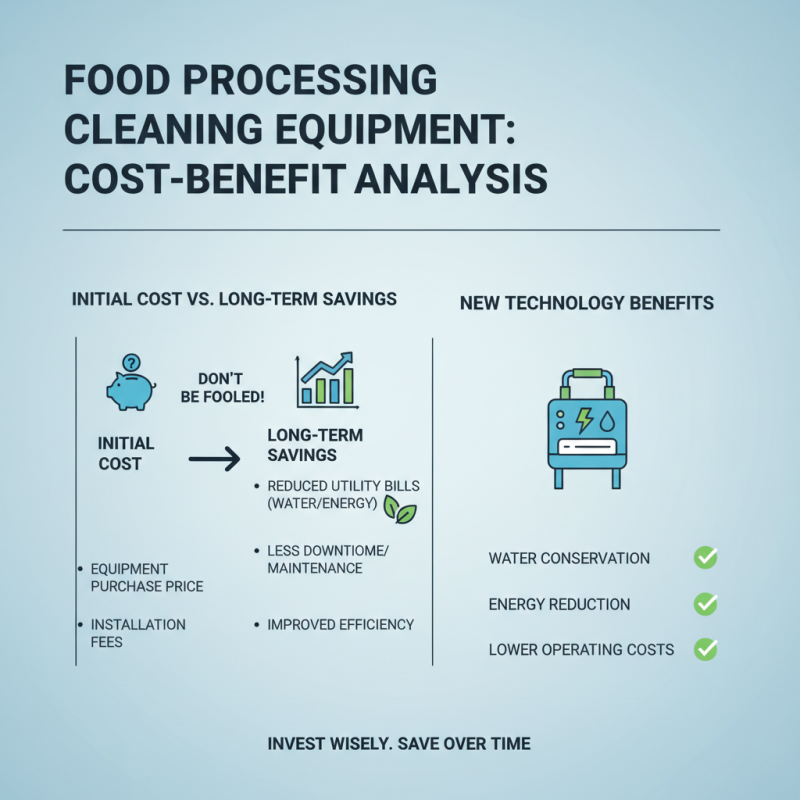

When evaluating food processing cleaning equipment, a cost-benefit analysis is essential. The initial cost isn't everything. Consider the long-term savings. Some equipment may seem cheap at first but can lead to higher recurring costs. Newer technologies often reduce water and energy consumption. This can save money on utility bills over time.

Tips: Look for energy-efficient options. Analyze how much water is used. Affordable doesn't always mean cost-effective.

Another factor is maintenance. Some machines require frequent repairs or replacements. This leads to unexpected expenses. Calculate the total cost of ownership rather than just the purchase price. Think about the time lost during equipment downtime. This can affect productivity and food safety.

Tips: Research maintenance records. Ask for user reviews. A reliable machine minimizes headaches in the long run.

Lastly, consider the training needed for operators. Some equipment may require specialized skills. This could mean additional training costs that add up. Reflect on how easy it will be to operate and maintain the equipment. The best choice balances upfront costs with efficiency and reliability.

JK Machinery a.s.

Psohlavců 322/4, Praha 4,

Czechia

T: +420 777 610 380

E: sale@roll-formingmachinery.com