Horizontal equipment plays a pivotal role in various industrial applications, providing essential functionalities that enhance operational efficiency. This term refers to machines and systems that are oriented horizontally, which can significantly impact the workflow and productivity in numerous sectors including manufacturing, construction, and agriculture. Understanding the characteristics, types, and applications of horizontal equipment can offer insights into how these tools can advantageously fit into an organization's processes.

The versatility of horizontal equipment is one of its greatest strengths, as it comes in numerous forms suited for multiple tasks. From horizontal boring machines to horizontal tank systems, each type has unique features that cater to specific needs. As industries continue to evolve, so does the technology behind horizontal equipment, leading to improved designs that enhance performance and durability. This article delves into the different types of horizontal equipment, their uses, and the benefits they confer, providing a comprehensive overview for anyone looking to leverage these tools for increased efficiency in their operations.

Horizontal equipment refers to a category of machinery and tools that are oriented horizontally, as opposed to vertically. This design choice allows for a variety of applications across different industries, including construction, manufacturing, and agricultural processes. The horizontal orientation often facilitates easier loading and unloading of materials, enhancing efficiency in operations. This type of equipment can encompass everything from conveyors and compressors to mixers and tanks.

The importance of horizontal equipment in industrial settings cannot be overstated. These machines optimize space and improve workflow, allowing companies to manage resources effectively. By utilizing horizontal equipment, industries can achieve higher productivity levels while minimizing the risk of accidents, as this design promotes stability. Furthermore, the versatility of horizontal equipment allows it to adapt to various tasks, making it a valuable asset in maintaining operational flexibility across multiple sectors.

Horizontal equipment refers to machinery and tools designed to operate in a horizontal orientation, widely used across various industries for specific applications. One prominent type of horizontal equipment is horizontal milling machines, which are essential in manufacturing for shaping and cutting materials with precision. These machines excel in producing flat surfaces, grooves, and complex shapes, making them invaluable in automotive and aerospace industries.

Another vital category includes horizontal mixing equipment, often used in the food processing, chemical, and pharmaceutical sectors. These mixers ensure uniform blending of materials, crucial for product consistency and quality. Horizontal mixers are particularly effective for incorporating dry powders, granules, and liquids, enhancing efficiency and reducing the time required for mixing compared to vertical counterparts. Each type of horizontal equipment plays a significant role in enhancing production capabilities while ensuring specific industry requirements are met effectively.

| Type of Horizontal Equipment | Common Uses | Benefits | Specific Applications |

|---|---|---|---|

| Horizontal Band Saw | Cutting materials like metal and wood | High precision and efficiency | Manufacturing, woodworking, metalworking |

| Horizontal Mixer | Mixing dry and wet ingredients | Uniform mix and reduced processing time | Food processing, chemical manufacturing |

| Horizontal Boring Mill | Machining large components | Precision machining of large parts | Aerospace, automotive, heavy machinery |

| Horizontal Shaft Impact Crusher | Crushing rock and aggregates | High reduction ratio and efficient processing | Mining, construction, recycling |

| Horizontal Laser Cutting Machine | Cutting intricate shapes in various materials | High efficiency and clean edges | Manufacturing, signage, artistic designs |

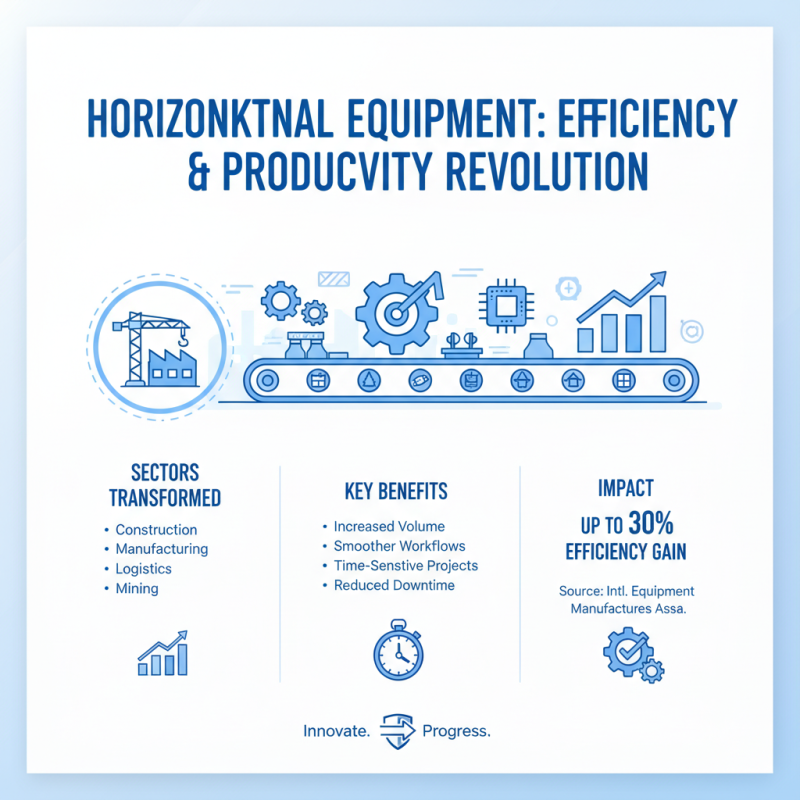

Horizontal equipment plays a pivotal role across various sectors, offering several key benefits that enhance efficiency and productivity. According to the International Equipment Manufacturers Association, the use of horizontal equipment, particularly in construction and manufacturing, has been shown to improve operational efficiency by up to 30%. This is primarily due to their ability to handle larger volumes of materials and facilitate smoother workflows, which is essential in time-sensitive projects.

In the mining sector, for instance, horizontal equipment such as conveyor systems and hydraulic excavators significantly reduce bottlenecks during material transport. A study by the Mining Industry Journal revealed that implementing horizontal equipment in mining operations can lead to a 25% reduction in transport time compared to traditional vertical systems. Similarly, in agriculture, horizontal farming equipment enhances crop yield and soil management, with a report from the Agricultural Equipment Association indicating that farmers utilizing horizontal tillage techniques experienced an average increase of 15% in their annual harvests. These advantages not only streamline processes but also lead to cost savings and sustainability improvements.

Maintenance and operational considerations for horizontal equipment are crucial for ensuring longevity and optimal performance. Regular inspections should be conducted to identify wear and tear, as well as to check for any alignment issues that might affect functionality. This includes monitoring components such as bearings, belts, and motors, which can significantly impact efficiency if not properly maintained. Implementing a proactive maintenance schedule can help prevent unexpected breakdowns and prolong the equipment's operational life.

In addition to routine inspections, operational practices play a vital role in maintaining horizontal equipment. Operators should be trained to follow best practices in usage, including load handling and speed management, to minimize strain on the equipment. Proper training ensures that operators are aware of the equipment's limitations and can recognize early signs of malfunction. Also, keeping equipment clean and free of debris not only improves performance but also reduces the risk of contamination, which could lead to more serious issues. By focusing on these maintenance and operational considerations, organizations can enhance both the reliability and efficiency of their horizontal equipment.

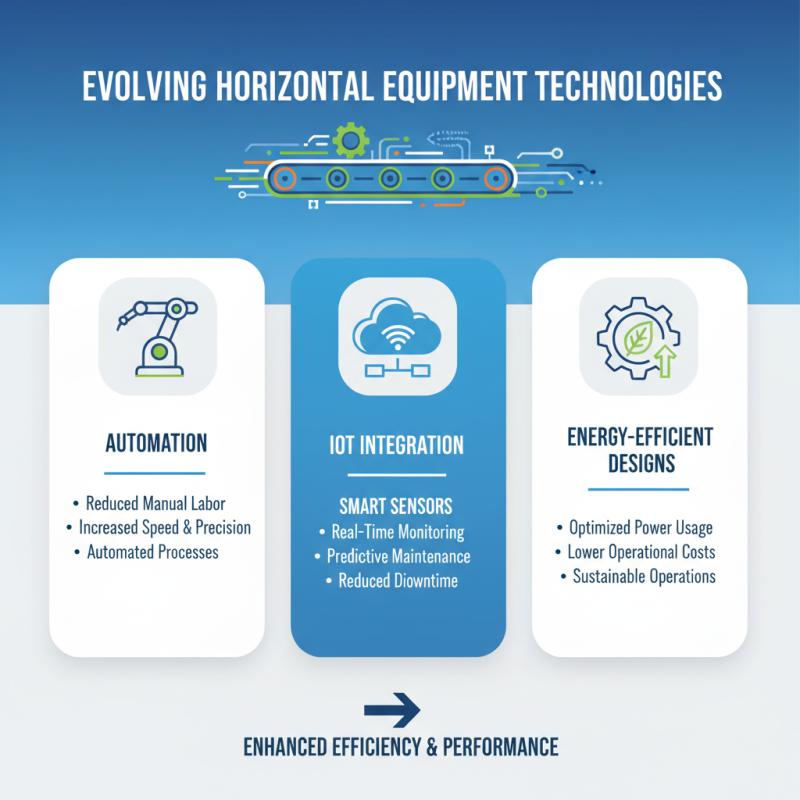

The landscape of horizontal equipment technologies is continuously evolving, driven by innovations that enhance efficiency and performance across various industries. Recently, advancements such as automation, IoT integration, and energy-efficient designs have emerged, revolutionizing how horizontal equipment operates. For instance, the incorporation of smart sensors allows for real-time monitoring and predictive maintenance, reducing downtime and operational costs significantly.

Tips: When selecting horizontal equipment, consider investing in technologies that offer IoT capabilities. This not only facilitates better monitoring but also improves data collection, enabling informed decision-making.

Additionally, trends such as 3D printing and advanced materials are changing the way horizontal equipment is designed and manufactured. These innovations provide greater customization and speed up production times, ensuring that equipment can be tailored to specific needs quickly and cost-effectively. As industries strive for sustainability, the adoption of lighter and more durable materials further contributes to reduced energy consumption and lower environmental impact.

Tips: Stay updated on industry trends to leverage new technologies that can enhance your workflow. Participating in webinars or conferences can provide valuable insights into cutting-edge practices in horizontal equipment technologies.

JK Machinery a.s.

Psohlavců 322/4, Praha 4,

Czechia

T: +420 777 610 380

E: sale@roll-formingmachinery.com