The efficiency of food processing operations is crucial in meeting the increasing demand for safe and high-quality food products. One of the key factors that contribute to this efficiency is the thoughtful design of food processing equipment. In an ever-evolving industry, where technological advancements and consumer preferences are constantly shifting, prioritizing effective equipment design can lead to significant improvements in productivity and resource management.

The design of food processing equipment incorporates various principles that address operational flow, sanitation, and ease of maintenance. By adopting innovative design strategies, manufacturers can minimize waste, enhance workflow, and ultimately reduce production costs. Moreover, well-designed equipment can adapt to changing regulatory standards and consumer trends, ensuring that businesses remain competitive in a dynamic market.

As we explore the top tips for the design of food processing equipment, it becomes evident that a strategic approach not only uplifts operational efficiency but also nurtures sustainability within the food industry. The subsequent sections will delve into key aspects such as ergonomics, technological integration, and scalability that can significantly contribute to the overall effectiveness of food processing systems.

Ergonomic design in food processing equipment is critical in enhancing workplace efficiency and ensuring the well-being of operators. According to the National Institute for Occupational Safety and Health (NIOSH), ergonomic interventions can reduce workplace injuries by as much as 50%, significantly lowering costs associated with worker absenteeism and healthcare. By focusing on ergonomics, food processing facilities can optimize the physical interaction between workers and machines, which is essential in a sector that often involves repetitive tasks and heavy lifting.

Implementing ergonomic principles entails designing equipment that fits the natural movements of workers. For instance, adjustable work surfaces and machine heights can accommodate individuals of varying statures, thereby reducing strain and fatigue. A report from the British Occupational Health Research Foundation highlights that ergonomic adjustments lead to improved productivity by 25% in food processing environments. Simple changes, such as the incorporation of easy-to-use handles, non-slip surfaces, and intuitive controls, can streamline operations while fostering a safer working atmosphere. Emphasizing these ergonomic factors not only benefits employees but also enhances overall equipment efficiency, ultimately contributing to higher output and better quality in food production processes.

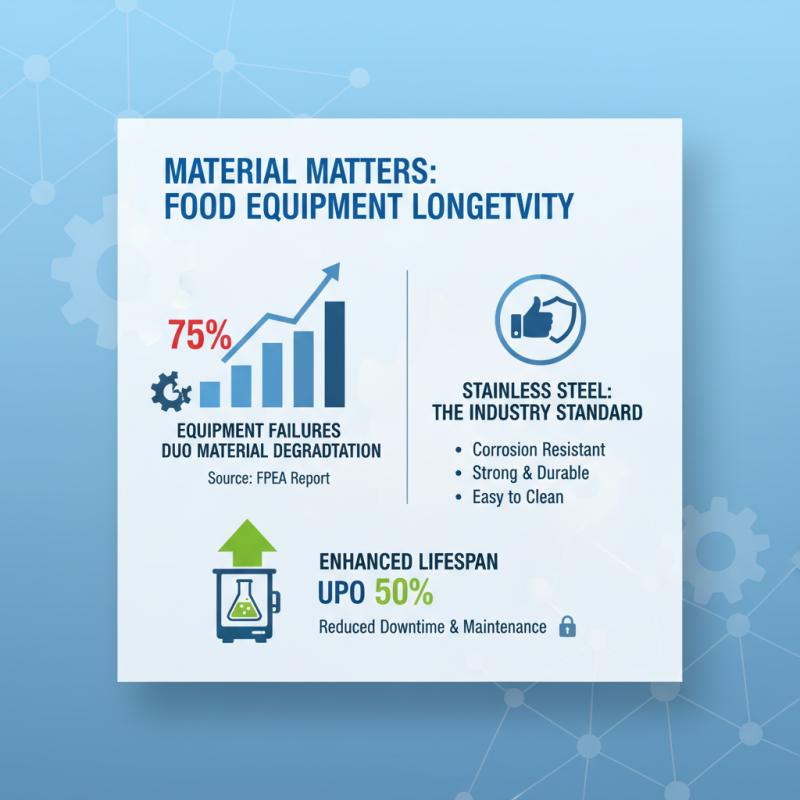

In the food processing industry, the selection of materials plays a crucial role in ensuring both durability and hygiene of equipment. According to a report from the Food Processing Equipment Association (FPEA), around 75% of equipment failures are attributed to material degradation, highlighting the importance of choosing the right materials. Stainless steel remains one of the most preferred choices due to its excellent corrosion resistance, strength, and ease of cleaning. It has been shown that using high-quality stainless steel can enhance the lifespan of processing equipment by up to 50%, significantly reducing downtime and maintenance costs.

Another critical aspect to consider is the hygiene element of materials used in food processing. The Centers for Disease Control and Prevention (CDC) states that foodborne illnesses affect 1 in 6 Americans each year, emphasizing the importance of sanitation. Materials that are non-porous, such as certain types of aluminum and specialty polymers, are increasingly being adopted due to their ability to minimize bacterial growth and facilitate easier cleaning processes. In fact, the USDA recommends specific materials for processing environments that can withstand rigorous cleaning and sanitization protocols, which is essential for maintaining compliance and ensuring food safety standards.

The incorporation of flexibility and modularity in the design of food processing equipment plays a crucial role in enhancing operational efficiency. In today's dynamic food industry, manufacturers face the challenge of adapting to changing market demands and diverse product lines. A modular design allows for the easy configuration and reconfiguration of equipment, enabling companies to scale operations up or down without the need for extensive retooling. This adaptability not only reduces downtime during transitions but also supports the quick introduction of new products, thereby enhancing competitiveness.

Moreover, flexible equipment designs facilitate seamless integration with existing systems. By allowing for interchangeable parts and adjustable components, processors can optimize their workflows and reduce bottlenecks in production. This is particularly beneficial in environments with varying production volumes, where the ability to switch between product types efficiently can lead to significant time and cost savings. The focus on modular designs not only empowers manufacturers to respond swiftly to market trends but also fosters innovation by enabling easier experimentation with new processing techniques and recipes.

In the fast-evolving landscape of food processing, leveraging technology is crucial to optimizing workflow efficiency. According to the Food Processing Technology report, businesses that adopt advanced automation technologies can increase their productivity by up to 30%. This dramatic boost is largely attributed to robotic process automation (RPA) and smart sensors that streamline repetitive tasks, minimize human error, and allow for real-time data monitoring. With operational efficiency at the forefront, manufacturers are increasingly investing in integrated systems that facilitate seamless communication between equipment, reducing bottlenecks and shortening production cycles.

Moreover, employing data analytics tools plays a vital role in enhancing workflow efficiency. A study by the Food Industry Association found that organizations utilizing predictive analytics reported a 20% decrease in processing delays. By analyzing patterns and forecasting potential issues, food processors can proactively adjust their operations to maintain consistent output. These technological applications not only optimize resource allocation but also lead to significant cost savings. As the industry continues to embrace digital transformation, the implementation of smart technologies will remain a key driver in achieving higher efficiency and sustainability in food processing operations.

| Tips | Description | Technology Implementation | Expected Benefits |

|---|---|---|---|

| Modular Design | Utilize modular components for flexibility in equipment configuration. | 3D modeling software for rapid changes. | Enhanced adaptability to production changes. |

| Automation | Integrate automation for repetitive tasks and processes. | Use of AI-driven robotics in assembly lines. | Reduced labor costs and improved precision. |

| Energy Efficiency | Implement energy-saving technologies in machinery. | Smart sensors to monitor energy consumption. | Lower operational costs and environmental impact. |

| Predictive Maintenance | Utilize data analytics to predict equipment failures. | IoT devices to monitor machinery health. | Minimized downtime and extended equipment lifespan. |

| Ergonomic Design | Design equipment that improves worker ergonomics. | Adjustable workstations and tools. | Increased worker safety and productivity. |

| Quality Control Systems | Incorporate real-time quality monitoring. | Computer vision and sensors for defect detection. | Higher product consistency and reduced waste. |

| Sustainable Practices | Utilize sustainable materials and processes. | Biodegradable materials and waste reduction technologies. | Increased market competitiveness and brand loyalty. |

When designing food processing equipment, adhering to food safety regulations is paramount. Regulatory frameworks, such as those set by food safety authorities, dictate specific standards that equipment must meet to ensure the safety of food products. This includes materials that are non-toxic and easy to clean, as well as designs that minimize contamination risks. Incorporating features like smooth surfaces and seamless welds can significantly reduce the possibility of bacterial growth, thus playing a crucial role in maintaining hygiene throughout the food production process.

In addition to the physical design of the equipment, attention must also be paid to operational aspects that affect safety compliance. Implementing user-friendly controls and intuitive interfaces can help operators maintain proper hygiene and follow safe practices during operation. Training programs should ensure that all personnel are well-informed about the compliance requirements associated with the equipment. By integrating safety into the design phase and fostering a culture of food safety within operations, manufacturers can enhance not only compliance but also the overall efficiency of food processing systems.

JK Machinery a.s.

Psohlavců 322/4, Praha 4,

Czechia

T: +420 777 610 380

E: sale@roll-formingmachinery.com